Beer Spoilage Organisms

Beer Spoilage Organisms

by Katelyn Nishimoto, BSI Microbiologist

Making quality beer is a dynamic and rewarding experience that incorporates the living world around us. First and foremost, successful brewing can be directly attributed to the skill of the brewer. However, regardless of their skill, brewers must develop a regimen of regular microbial detection throughout the brewing process. The key is to maintain healthy environments for certain microorganisms but not for others. In doing so, brewers can reap consistent results while minimizing batch losses.

The good news: beer generally provides a rather unwelcoming environment for microorganisms other than yeast. Due to beer’s high ethanol content, low pH, nearly anaerobic atmosphere (due to the high concentration of CO2), the inhibitory effect of hop iso-alpha acid, and the limited nutrient supply, few microorganisms can survive in it. The bad news: despite these factors some microorganisms have adapted to flourish in such an inhospitable environment.

Unfortunately, these microbes can spoil beer by producing undesirable odors like hydrogen sulfide (rotten egg smell), creating adverse off-flavors like diacetyl (buttery taste), generating issues with turbidity, as well as affecting attenuation rates. The three main categories for beer-spoiling organisms are obligate (always causes spoilage), potential (only grows within certain environments like low alcohol or light hops), and indirect (contaminates the used raw materials). Let us focus primarily on the obligate variety.

Unfortunately, these microbes can spoil beer by producing undesirable odors like hydrogen sulfide (rotten egg smell), creating adverse off-flavors like diacetyl (buttery taste), generating issues with turbidity, as well as affecting attenuation rates. The three main categories for beer-spoiling organisms are obligate (always causes spoilage), potential (only grows within certain environments like low alcohol or light hops), and indirect (contaminates the used raw materials). Let us focus primarily on the obligate variety.

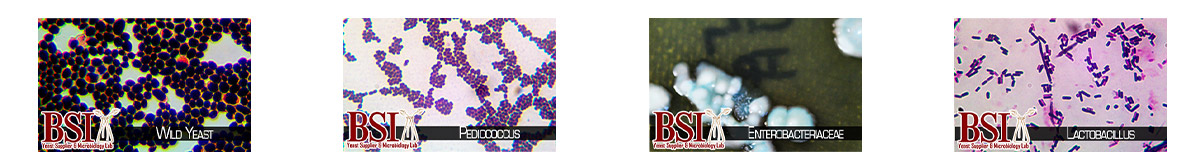

The Lactobacillus, one of the most common beer spoilers, is often hop resistant and can cause the beer to taste sour (from the lactic acid it produces) and consists of a silky turbidity. L. brevis, a popular strain of the Lactobacillaceae family, survives so well in beer that it has been isolated for use in some sour beer recipes. Pediococcus, another common hop-resistant bacterium, will produce a viscous beer by forming beta-glucans. This gives beer a “rope consistency,” increases acidity, and yields a buttery taste from the off-flavor diacetyl. Gram positive bacteria, like Lactobacillus and Pediococcus, are major obligate contaminates as they can tolerate high temperatures and high acidity.

Additionally, Brettanomyces bruxellensis, a wild yeast strain, can create an excess of phenolic compounds and carboxylic acids that produce a “musty” aroma, a “horsey” off-flavor, and a high attenuation that can cause over-carbonation resulting in burst bottles.

Additionally, Brettanomyces bruxellensis, a wild yeast strain, can create an excess of phenolic compounds and carboxylic acids that produce a “musty” aroma, a “horsey” off-flavor, and a high attenuation that can cause over-carbonation resulting in burst bottles.

A notable group of microorganisms now becoming more common in breweries are Zymomonas, Pectinatus, and Megasphaera. These gram-negative bacteria can interfere with the brewing process by producing undesired, beer-spoiling byproducts. These bacteria oxidize ethanol into acetic acid which results in vinegary off-flavors. Brewers have also noticed these bacteria occasionally surviving the fermentation process to become part of the finished beer. For example, Zymomonas, found frequently on brewing equipment and in water, can ferment glucose to alcohol in such a way that it produces an estery-sulfury flavor and adverse turbidity.

Finally, Enterobacteriaceae are unique in that they are considered wort spoilers, not beer spoilers. This is due to their sensitivity to the high alcohol and pH levels in beer. Instead, these microorganisms often thrive on the nutrients in the wort and can thus indirectly affect the flavor profile of the beer.

Because spoilage microorganisms introduce a myriad of contamination risks that may result in losses or recalls, it is critical that brewers test for them at every stage and area of production. Traditional monitoring and testing techniques rely on enrichment in culture media for several days. Because this is time-consuming and may be production-prohibitive, PCR tests that produce results within hours are becoming more popular. Click here to visit the BSI PCR testing service page.

For many years, following good prophylactic practices has been common tactics for minimizing beer contamination. However, relying on these methods alone is risky as they rely on operator competency, consistency, and effectiveness. Other modern approaches include flash pasteurization and sterile filtration using an innovative filter. Sterile filtration is the microfiltration of beer to remove any spoilage microorganisms before packaging and is a reliable technique for eliminating contaminating microbes from beer.

In addition, compounds such as Nisin have been shown to inhibit the growth of the gram-positive strains (predominantly lactic acid bacteria of the genera Lactobacillus and Pediococcus) by 92%. Therefore, Nisin has potential applications in preventing spoilage of worts or beers by lactic acid bacteria. This in turn, may ensure a good shelf life, retain the beer’s essential characteristics, and significantly reduce brewing costs.

For direct assistance on preventing contaminants in your brewery, become a valued BSI customer. BSI customers have access to free technical support. Our team of highly experienced and knowledgeable technical professionals is well-equipped to answer your brewing contaminant questions and more.

For direct assistance on preventing contaminants in your brewery, become a valued BSI customer. BSI customers have access to free technical support. Our team of highly experienced and knowledgeable technical professionals is well-equipped to answer your brewing contaminant questions and more.

For a comprehensive resource on brewing, click here to download the renowned, Brewing without the Blindfold manual. It’s free! Here’s a sample of what you’ll find:

-Quick & Dirty “Film Test” for Bottled Beer

-Detecting Bacteria, Wild Yeast & Petite Mutants with Selective Media

-Wort Stability Test

-Gram Staining

-Strain Purification

-Yeast Harvest and Storage

-Cell Counting

-Table of Brewing Bacteria

-Quick Reference Calculations and Conversions

-….and Much More

References

https://mmbr.asm.org/content/77/2/157

http://blog.parker.com/microbial-control-what%E2%80%99s-spoiling-my-beer

http://www.beer-brewing.com/beer_brewing/beer_brewing_chapters/ch19_beer_spoilage_organisms.htm

https://wine.appstate.edu/sites/wine.appstate.edu/files/NonSaccharomyces_Beer%20Spoilage%20Organisms.pdf

https://www.sciencedirect.com/science/article/abs/pii/0168160596011543

https://www.sigmaaldrich.com/analytical-chromatography/microbiology/identification-tests/hybriscan-rapid-test.html

https://www.labmanager.com/how-it-works/a-rapid-test-system-for-food-beverage-microbiology-17319

https://www.tandfonline.com/doi/abs/10.1094/ASBCJ-50-0064

https://onlinelibrary.wiley.com/doi/abs/10.1002/j.2050-0416.1985.tb04361.x

https://www.sciencedirect.com/science/article/abs/pii/S0168160503001533

http://chimie-biologie.ubm.ro/carpathian_journal/Papers_11(3)/CJFST11(3)2019_5.pdf