This is more than just a glossary of brewing industry terminology, it’s an effective troubleshooting guide for understanding and resolving common brewing issues. Here you’ll find key information to help you overcome undesired results such as off-flavors, excessive levels of diacetyl, cell death, abnormal fermentation and more. Use the interactive glossary of brewing terminology as your go-to troubleshooting resource.

Glossary

A

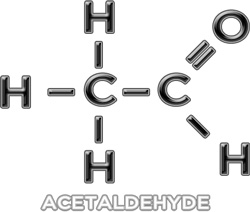

FACTS

- high flavor and staling potential

- formed by yeast in the glycolytic pathway

- reduced during conditioning

CAUSES

- over-aeration

- deficiency of zinc

- deficiency of vitamins

EFFECTS

- responsible for “green” flavor in fresh beer

FACTS

- responsible for lowering pH during fermentation

EXAMPLES

- acetic (vinegar)

- butyric, isobutyric (butter)

- capric, caproic, caprylic (soap, sweat, goat)

- citric (tart)

- formic

- lactic

- malic

- oxalic

- oleic, linoleic

- propionic

- pyruvic

- valeric

CAUSES

- wort trub

- hop-staling

- by-products of yeast carbohydrate metabolism

EFFECTS

- some end as fatty acids responsible for off-flavors

% ALCOHOL BY WEIGHT

- 42 (°P original gravity – °P final gravity)

% ALCOHOL BY VOLUME

- (alcohol by weight x specific gravity of beer) / 0.791

FACTS

- high flavor and staling potential

EXAMPLES

- trans-2-nonenal

- furfural

CAUSES

- formed in Browning reactions during malting and mashing

- can increase or decrease during fermentation

EFFECTS

- responsible for “stale”, “paper” and “cardboard” flavors

EXPECTED VALUES

- dark ale = 68-75%

- lager = 78-86%

- pilsner = 80-85%

- light = 100%

% APPARENT ATTENUATION

- °Plato of original wort – °Plato of final wort / °Plato of original wort

FACTS

- condensation product of an alcohol and an acid

EXAMPLES

- isoamyl acetate (banana)

- ethyl acetate (apple)

CAUSES

- produced during yeast lipid synthesis

- yeast strains differ in their production

- high pitch rate – low levels

- high fermentation temperature – high levels

- high aeration – low levels

- high gravity – low levels

- high pressure – low levels

- high fatty acid content – low levels

EFFECTS

- “fruit” flavors

B

FACTS

- produced by all yeasts and some bacteria during amino acid synthesis

- reduced to a less-flavorful compound (2,3-butanediol) by yeast during conditioning

CAUSES OF HIGH LEVELS

- underpitching

- highly-flocculant yeast strain

- inadequate diacetyl rest

- bacterial contamination

- high petite-mutant population

EFFECTS OF HIGH LEVELS

- “butter” flavor

- slick mouth-feel

FACTS

- condensation product of an alcohol and an acid

EXAMPLES

- isoamyl acetate (banana)

- ethyl acetate (apple)

CAUSES

- produced during yeast lipid synthesis

- yeast strains differ in their production

- high pitch rate – low levels

- high fermentation temperature – high levels

- high aeration – low levels

- high gravity – low levels

- high pressure – low levels

- high fatty acid content – low levels

EFFECTS

- “fruit” flavors

FACTS

- sugars and amino acids react during kilning and boiling to yield pigments

- also known as the Maillard reaction

C

FACTS

- utilization is a function of yeast genetics

- glucose inhibits the transport of maltose and maltotriose in lager yeasts

SUGARS IN ORDER OF YEAST PREFERENCE

- glucose (diffuses through cell wall)

- fructose (diffuses through cell wall)

- sucrose (converted to glucose and fructose by invertase in cell wall)

- maltose, maltotriose (transported through cell wall, then converted to glucose)

FACTS

- passes through yeast cell wall in solution, not as a gas

- forms bubbles at nucleation sites such as trub particles and cell-wall exteriors

- removes volatile sulfur compounds as bubbles rise to surface

- can be present in super-saturated levels at fermentor bottom

CAUSES OF HIGH WORT LEVELS

- too little trub in wort

- fermentor is under pressure

EFFECTS OF HIGH WORT LEVELS

- decreases ester production

- inhibits yeast growth

- slows rate of fermentation

FACTS

- 40-60 million cell/ml needed in suspension for proper effect

D

FACTS

- produced by all yeasts and some bacteria during amino acid synthesis

- reduced to a less-flavorful compound (2,3-butanediol) by yeast during conditioning

CAUSES OF HIGH LEVELS

- underpitching

- highly-flocculant yeast strain

- inadequate diacetyl rest

- bacterial contamination

- high petite-mutant population

EFFECTS OF HIGH LEVELS

- “butter” flavor

- slick mouth-feel

CAUSES IN WORT

- excessive build-up of copper

- over-sparging of mash, leaching toxic polyphenol-protein complexes into wort

- high nitrite levels in brewing water (>25ppm)

- insufficient wort aeration

- high levels of unsaturated fatty acids

CAUSES IN SLURRY

- over-aeration of slurry with pure oxygen

- high temperature, insufficient nutrients

E

FACTS

- condensation product of an alcohol and an acid

EXAMPLES

- isoamyl acetate (banana)

- ethyl acetate (apple)

CAUSES

- produced during yeast lipid synthesis

- yeast strains differ in their production

- high pitch rate – low levels

- high fermentation temperature – high levels

- high aeration – low levels

- high gravity – low levels

- high pressure – low levels

- high fatty acid content – low levels

EFFECTS

- “fruit” flavors

F

SYMPTOMS

- high carbon dioxide evolution

CAUSES

- large amounts of trub

- wort is too chilled

- uneven temperature profile

- uneven yeast distribution

- over-modified malt

- build-up of beerstone

- excessive wort maltose

- unusual characteristics of yeast

SOLUTIONS

- break up yeast by aerating

- remove more trub from wort

SYMPTOMS

- slow, bubbling fermentation, usually appearing after krausen stage

CAUSES

- degenerated or autolyzed yeast

- poor trub elimination

- sudden temperature increase

- poor cellar ventilation

- presence of nitrites

- highly kilned malts

SOLUTIONS

- pump wort into another fermentor

- add vigorous, roused yeast

SYMPTOMS

- slow or no fermentation

CAUSES

- insufficient wort aeration

- lack of fermentable sugars in wort

- wort pH too high (over 5.5)

- fermentor and wort too cold, causing yeast to flocculate

- yeast lacks enzymes need to ferment maltotriose

- weak or degenerated yeast

- inadequately cured malt

- antifoam agents or trub clogging yeast membrane

- extensively demineralized water

- extremely soft water

- water high in carbonate hardness

- high nitrate level (>25ppm)

- high copper content

SOLUTIONS

- add vigorous, roused yeast

- pump wort into another fermentor

- analyze to determine whether yeast is capable of fermenting wort sugar-profile

ADVANTAGES

- lower energy costs

- maximal use of equipment and space

- improved physical stability from better precipitation of chill haze

- improved flavor stability

DISADVANTAGES

- wort- and hop- efficiencies can be reduced

- increased yeast stress

- 50% or more yeast is needed

- number of yeast generations is reduced

- oxygen levels as high as 10-12pmm are needed

- increased cost of losses

- longer fermentation times

- decreased foam stability

- higher final pH

CAUSES IN WORT

- pH above 5.7

- temperature too close to low end of yeast’s fermentation range

- inadequate aeration (empty bottle/stuck regulator)

- insufficient nutrients (especially zinc)

- contamination

CAUSES IN YEAST SLURRY

- too warm storage conditions (over 34°F/1°C)

- too long storage time (greater than 48 hours if unfed)

- poor viability (less than 95%)

- contamination

GUIDELINES

- warm slurry to upper end of yeast’s fermentation range

- aerate if specific gravity has dropped less than 30% of expected total

- add zinc to wort

- add fresh, healthy yeast

FACTS

- by-product of protein synthesis from keto-acids

- have longer carbon-chain length than ethanol

EXAMPLES

- n-propanol (solvent)

- iso-butanol (solvent)

- 2-phenyl ethanol (medicinal)

- 2-methyl-1-butanol (aromatic)

- 3-methyl-1-butanol (spice)

CAUSES

- affected by wort amino acid composition

- high pitch rate – low levels

- high fermentation temperature – high levels

- high aeration – high levels

- high gravity – low levels

- high pressure – low levels

- high fatty acid content – low levels

EFFECTS

- fullness of flavor at low levels

- unpleasant at high levels

H

SYMPTOMS

- little or no foam though carbonation levels are adequate

CAUSES

- proteases released by autolyzing yeast

- unclean equipment

SOLUTIONS

- do not store yeast under finished beer

- clean and degrease equipment

- check for leaking pump-lubricant

FACTS

- normally purged during fermentation by carbon dioxide

CAUSES

- reduced from sulfite by yeast

- made by yeast from sulfur-containing amino acids

- produced most during budding

- degenerated pitching yeast

- some wort-spoiling bacteria

EFFECTS

- “rotten-egg” odor

L

LAG PHASE

- changes in pressure, temperature and nutrients

- biosynthesis of enzymes needed for metabolism

- oxygen rapidly removed from wort for sterol and fatty acid synthesis

LOGRITHMIC PHASE

- fast yeast reproduction

- uptake of nutrients and sugars

- heat is generated

- volatiles are driven off

DECLINING PHASE

- increase in acidity, alcohol and carbon dioxide

- utilization of glycogen and sterol reserves

- reproduction ceases

- flocculation

M

FACTS

- sugars and amino acids react during kilning and boiling to yield pigments also known as the Maillard reaction.

N

FACTS

- nitrogen content decreases 30% during fermentation

- large concentration of nitrogen is found in wort amino acids

- yeast assimilates nitrogen from amino acids and small proteins

- yeast will manufacture missing amino acids, yielding off-flavors, like phenylethanol (rose)

AMINO ACIDS IN ORDER OF YEAST PREFERENCE

- threonine

- methionine

- isoleucine, leucine

- valine

- tyrosine

- tryptophan

- phenylalanine

O

TEMPERATURE, °C : SATURATION, mg/l

- 5 : 10

- 6 : 9

- 10 : 8

- 15 : 7

FACTS

- more soluble at lower temperatures

- usually completely taken up within 2 hours of pitch

CAUSES

- yeast enzymes require oxygen to synthesize membrane building-blocks

EFFECTS

- deficiency restricts yeast growth

- deficiency reduces yeast viability

- deficiency impedes complete fermentation

- deficiency alters beer flavor

P

FACTS

- occurs very rapidly over the first 48 hours of fermentation

- usually spans at least 1 pH unit over fermentation period

- optimal pH for yeast is pH 4.0

CAUSES

- affected by any factor that affects yeast growth

- due 10% to formation of carbon dioxide

- due 20% to formation of organic acids (lactic, succinic, oxalic)

- due 40% to absorption of alkaline substances such as phosphates and amino acids

EFFECTS

- extreme drop produces a less mellow, more astringent, drier-tasting beer

EXAMPLES

- 4-vinyl-guiacol (clove)

- 4-ethyl-guiacol (nutmeg)

CAUSES

- malt and hops

- weiss yeast conversion of ferulic acid

EFFECTS

- “spice” flavors

PRESSURE, HIGH (high fermentation pressure):

CAUSES

- exceedingly tall fermentors

- obstructed blow-off

EFFECTS

- increases FAN in resulting beer

- increases vicinal diketones and diacetyl

- increases acetaldehyde

- decreases yeast growth

- decreases ethyl acetate

- decreases fusel alcohols

S

FACTS

- specific gravity uses pure water as a reference

- wort contains fermentable sugars which raise the specific gravity

CAUSES OF DROP IN

- yeast metabolize sugars

- soluble substances are used by yeast

- alcohol, which is less dense than water, increases

- carbon dioxide is produced

FACTS

- very low flavor threshold

EXAMPLES

- DMS

- hydrogen sulfide

- sulfite

- thiols

CAUSES

- malt, hops and yeast metabolism

- stressed or autolyzing yeast

EFFECTS

- low levels impart fullness

- high levels are very unpleasant

FACTS

- an intermediate in the synthesis of sulfur-containing amino acids

CAUSES

- derived from wort sulfate

- reduced to sulfite by yeast

- factors which retard yeast growth will increase levels

EFFECTS

- complexing with acetaldehyde leads to early staling

T

FACTS

- fermentation is an exothermic, biochemical reaction

- every kg of extract fermented produces 140kcal of heat

CAUSES OF LOW TEMPERATURES

- over-zealous wort-cooling

- cold ambient temperatures

EFFECTS OF LOW TEMPERATURES

- increases fermentation time

- encourages yeast to flocculate

- ale yeasts produce more sulfur compounds

CAUSES OF HIGH TEMPERATURES

- inefficient or malfunctioning glycol system

EFFECTS OF HIGH TEMPERATURES

- decreases fermentation time

- decreases acetaldehyde

- increases fermentation by-products

- increases ethyl acetate

- increases fusel alcohols

ALES

- between 15-20°C / 60-70°F

LAGERS

- between 8-13°C / 45-55°F

FACTS

- levels may decrease during storage

EXAMPLES

- methanethiol

- methylmercaptan

- methylthioacetate

CAUSES

- related to yeast amino acid synthesis

EFFECTS

- “young” flavor and aroma

- “light-struck” character if exposed to ultraviolet light

W

FACTS

- precipitates chill haze proteins

- encourages yeast flocculation

GUIDELINES

- do not exceed drop rate of 20°F / 10°C per hour

Y

LAG PHASE

- changes in pressure, temperature and nutrients

- biosynthesis of enzymes needed for metabolism

- oxygen rapidly removed from wort for sterol and fatty acid synthesis

LOGRITHMIC PHASE

- fast yeast reproduction

- uptake of nutrients and sugars

- heat is generated

- volatiles are driven off

DECLINING PHASE

- increase in acidity, alcohol and carbon dioxide

- utilization of glycogen and sterol reserves

- reproduction ceases

- flocculation

Z

FACTS

- optimal wort level is 0.25ppm

EFFECTS

- high levels lead to higher ester production

- high levels encourage yeast flocculation