Non-Alcoholic Beer: Everything You Need to Know!

The History of NA Beer

In 1920, the United States passed the Volstead Act (Giambrone). This 13-year ban on the consumption and transportation of alcoholic beverages jump-started the reformation of beer into “near beer” or “tonics”’ in an attempt to keep business coming for many brewers during this time. The use of low gravity beer, and boiling of the product, lowered the ABV to the legal limit of 0.5% alcohol by volume or below (NA Beer Club). The pioneers for these brews were Pabsts’ Pablo and Anheuser-Busch’s Bevo. However, these “beers” did not remain popular after the end of Prohibition in 1933 due to their unremarkable taste.

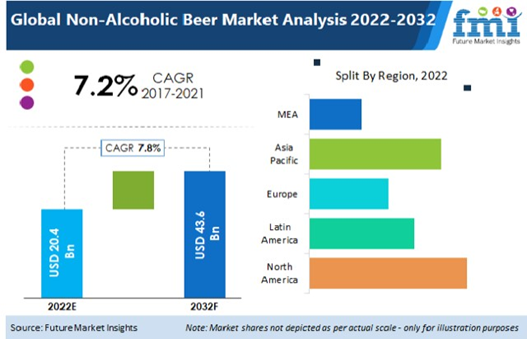

Unlike 1920, the last 20 years have seen a significant resurgence of NA brews and breweries due in part to health, fitness, and the growth of craft breweries. Restaurants and bars are also jumping on this by offering NA options to their patrons as well (Fallert). The sales from 2016 to 2019 increased by 23% for NA beer in the US beer market with an overall monetary increase of over 100 million USD (Beer Maverick). By 2026, the US market will have an intake of $6.4 billion and the world beer market raking in $29 billion (Beer Maverick). In addition, Future Market Insights claims the compound annual growth rate, or CAGR, of the global NA beer market will double by 2032. This expansion comes in part to increased educational resources, like books and podcasts, addressing sobriety and mental health journeys of individuals growing in popularity, specifically amongst millennials (Fallert).

How to Make a Tasty Non-Alcoholic Brew

How to Make a Tasty Non-Alcoholic Brew

If you’re wanting to hop on this trend as an established brewery, you can employ multiple different techniques to accomplish a NA brew. Many of the methods used today result in much higher power consumption and more parts than your typical set-up. These methods can include biological processes, thermal processes, extraction processes, and membrane processes. These techniques boil down to two key principles: restricting the synthesis of ethanol or removing the ethanol (Muller).

Now, let’s dive deeper into a few of the most common techniques used by brewers past and present. These techniques involve restricting the synthesis of ethanol or removing the ethanol (Muller).

Reverse Osmosis

Reverse osmosis is a common extraction method that has relatively low energy costs and a strong future through developmental improvements (Muller). Osmosis is the common physical process that involves the movement of water and solutes across a selective, semi-permeable membrane to reach an equilibrium. In reverse osmosis, opposing pressure pushes alcohol and water in beer against the concentration gradient through the membrane. The membrane is unable to restrict the movement of aromatic compounds along with the alcohol, as a result, the flavor of the beer is impacted and will be slightly more acidic. Advancements in the industry are being made to remedy this occurrence. (Muller).

Ethanol Removal

While very effective, the removal of ethanol through thermal reactions requires extra equipment and increased overhead costs due to the large amount of energy involved. However, the ability to retain and reintegrate volatile aromatic compounds back into the beer drastically improves the organoleptic properties of the brew (Muller). Two common processes in this category include vacuum distillation and spinning cone distillation (Mazzeo).

Vacuum distillation entails heating the beer to 45℃ while transferring the liquid to another chamber that will quickly reduce the pressure. This allows the volatile aromatic compounds to evaporate and be stored in a recombination tank. The alcohol is released at 40 ℃ while the beer is transferred through a spray condenser. A heat exchanger then cools the beer to 4 ℃ or 5 ℃, causing the removal of minerals and volatile compounds. Lastly, the beer is

refrigerated at 1 ℃, where it will then be mixed back in with the previously obtained aromatic compounds in the recombination tank. The reintroduction of these flavor compounds allows the brewer to retain a more ideal flavor profile (Muller).

refrigerated at 1 ℃, where it will then be mixed back in with the previously obtained aromatic compounds in the recombination tank. The reintroduction of these flavor compounds allows the brewer to retain a more ideal flavor profile (Muller).

The dealcoholization of wine is a very popular method involving a spinning cone distillation process (Mazzeo). This method requires an extensive apparatus consisting of multiple, large spinning cones. Beer is pumped onto heated cones, slowly flowing over to the other cones by centrifugal force. The heat from steam causes vaporization of the alcohol and other small molecules. These molecules are subsequently removed and re-condensed into a separate tank or chamber (Mazzeo). Increased pressure causes the beer to be extracted through an output disc. This process occurs within 10 seconds and can be done numerous times, dependent upon the desired alcohol content (Muller).

Arrested Fermentation

If new equipment is not in your budget, arrested fermentation may be your solution! This method is the process of preventing ethanol formation from occurring. It can be accomplished with strains that won’t break down complex sugars, or by removing yeast altogether before it is able to ferment/produce ethanol. Keep in mind that the latter causes the beer to be less desirable and less flavorful. The ethanol production occurs when the yeast resort to an anaerobic form of respiration once oxygen is no longer available. The complex sugar in the wort is broken down for energy and results in the production of ethanol (Lissner). Therefore, using yeast that cannot breakdown these sugars will prevent or reduce the amount of alcohol produced. For example, use BSI’s S.ludwigii , which is a widely used maltose negative strain that has been reported by several participants in a master thesis experiment to provide a “sweet” or “fruitier” flavor in comparison to traditional beer. This sweeter flavor is due to the small amount of maltose produced during mashing.

Not a Brewer, That’s OK!

NA beer is on the rise! It is a great way to practice honing a new skill in the brewing industry. If you are interested in cutting back on alcohol or wanting to explore the world of NA beer, try out the winners of the 2022 Great American Beer Festival held in Denver, Colorado. These are the perfect brews to start with. The winners included Just the Haze from Boston Beer Co. securing gold, Lemon Radler from Athletic Brewing Co. obtaining silver, and Nada IPA by Community Beer Co. leaving with bronze. Now, all that’s left to do is sit back, relax, and drink a pack, two, or more; I mean they are non-alcoholic after all!!

Call BSI today to order some S. ludwigii for your non-alcoholic brew today!

References:

Beer Maverick. (2021, March 30). The story behind craft non-alcoholic brews. Retrieved from https://beermaverick.com/the-story-behind-craft-non-alcoholic-brews/

Fallert, N. (2019, March 26). Why you’re likely going to hear more about being “sober curious”. Retrieved from https://www.vox.com/the-goods/2019/3/26/18267092/sober-curious-nonalcoholic-drinks-spirits

Future Market Insights, Inc. (2022, March). Non-alcoholic beer market. Future Market Insights. Retrieved from https://www.futuremarketinsights.com/reports/non-alcoholic-beer-market

Giambrone, J. (n.d.). Near beer and wine bricks: Loopholes and innovation during prohibition. Retrieved from https://www.historyassociates.com/near-beer-and-wine-bricks/

Lissner, L. (2018). Non-alcholic beer with maltose negative yeast strain Saccharomycodes ludwigii. [ Master Thesis, Lunds University]. Department of Food and Technology, Faculty of Engineering LTH.

Mazzeo, J. (2022, July 25). The science behind non-alcoholic beer and wine production. Retrieved from https://daily.sevenfifty.com/the-science-behind-non-alcoholic-beer-and-wine-production/

Muller, C., Neves, L. E., Gomes, L., Guimarãse, M., & Ghesti, G. (2020, April). Processes for alcohol-free beer production: A Review. Food Science and Technology, 40(2), 273-281. doi:10.1590/fst.32318

NA Beer Club. (2022, May 06). The history of non-alcoholic beer in America. Retrieved from https://nabeerclub.com/history-non-alcoholic-beer/

By: Katie Pesek, BSI Microtechologist