The Role of Dimethyl Sulfide (DMS) in Beer

The Role of Dimethyl Sulfide (DMS) in Beer: Understanding Its Impact

Dimethyl sulfide (DMS) is a sulfur-containing compound that can significantly influence the aroma and flavor of beer. While many consider it an undesirable presence, contributing to off-flavors, DMS can also be a key element in creating distinct beer characteristics, particularly when properly managed. This blog explores the nature of DMS in beer, its sources, effects, and ways brewers can control its levels for optimal flavor.

What is Dimethyl Sulfide (DMS)?

What is Dimethyl Sulfide (DMS)?

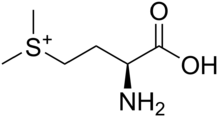

Dimethyl sulfide is an organic compound with a strong, somewhat unpleasant odor often described as “canned corn” or “vegetable-like.” It is a naturally occurring byproduct of the brewing process, particularly in lagers and certain ales. The precursor molecule S-methylmethionine (SMM) breaks down during the malting, brewing, and fermentation processes in turn, creating DMS.

“vegetable-like.” It is a naturally occurring byproduct of the brewing process, particularly in lagers and certain ales. The precursor molecule S-methylmethionine (SMM) breaks down during the malting, brewing, and fermentation processes in turn, creating DMS.

DMS is highly volatile. It can easily escape the beer if managed correctly, especially during brewing processes like boiling and fermentation. However, if not properly controlled, it can accumulate and result in a beer with off-flavors.

The Sources of DMS in Beer

The primary source of DMS in beer comes from malted barley, which contains SMM. When mashing and boiling malt, the SMM is converting into DMS by heat and enzymatic activity. This compound then enters the wort. If the boiling process is insufficient or if there is inadequate ventilation during fermentation, DMS can remain in the final beer.

Several factors contribute to the production of DMS during the brewing process:

- Malting: The amount of SMM in the malt depends on how it’s malted. Pale malts tend to have more SMM than roasted malts.

- Boiling: DMS is more likely to form when the wort is boiling at lower temperatures or for shorter periods. A longer, vigorous boil is effective in driving off DMS

- Cooling: If the wort is cooled too slowly or improperly, DMS can evaporate more slowly and remain in the beer.

- Fermentation: During fermentation, yeast can further break down any remaining DMSO (a byproduct of SMM degradation) into DMS. Proper fermentation temperature and oxygen management are critical for minimizing this.

- Contamination: Although it’s not the most common source of DMS today, it can still occur from bacterial contamination of wort. Wort-spoiling bacteria can convert DMSO in the wort into DMS. Ensuring proper sanitation will mitigate this issue.

How DMS Affects the Flavor and Aroma of Beer

While some sulfur compounds are desirable in beer, DMS is often perceived as a flaw. Its odor can range from sweetcorn to cooked vegetables. Most beer styles generally find both odors unwanted.

The flavor and aroma impact of DMS can vary depending on the beer style:

- Lagers: Lagers, particularly pale lagers, are more susceptible to DMS due to their typically lighter body and malt-forward character. DMS can easily become noticeable in these styles, where the malt flavor is more pronounced.

- Ales: Ales, especially those with more robust hops or strong fermentation flavors, can mask DMS to some degree. It’s still best to manage it carefully.

- High-Gravity Beers: Stronger beers with higher alcohol content might also allow DMS to be more noticeable, as the base malt’s influence is often more prominent.

The presence of DMS can lead to a lack of clarity in the beer’s flavor profile. This sulfurous off-flavor can mar the crisp, clean finish expected from a well-brewed lager. This off-flavor may create a less-than-ideal drinking experience.

Managing DMS in Brewing

Brewers have a variety of tools and techniques at their disposal to control and reduce DMS levels in beer:

- Longer Boil Times: The most effective way to reduce DMS during brewing is through an extended boil. The heat helps volatilize and evaporate the DMS. A 60 to 90-minute boil is standard, with a vigorous boil necessary to drive out any DMS precursors.

Proper Wort Cooling: Quickly cooling the wort after the boil helps minimize the risk of DMS formation. A slow cool-down can trap DMS in the beer, leading to undesirable flavors. Rapid chilling (using a wort chiller, for example) is essential to avoid this.

Proper Wort Cooling: Quickly cooling the wort after the boil helps minimize the risk of DMS formation. A slow cool-down can trap DMS in the beer, leading to undesirable flavors. Rapid chilling (using a wort chiller, for example) is essential to avoid this.- Yeast Selection: Some yeast strains are more prone to creating DMS during fermentation. Choosing a yeast strain known for producing clean fermentation profiles can help reduce the likelihood of DMS presence in the final beer.

- Fermentation Control: Maintaining an appropriate fermentation temperature is crucial. High temperatures may increase DMS formation, while low temperatures can slow down fermentation and leave excess SMM in the beer. A controlled fermentation environment is key to avoiding off-flavors.

- Malting Choices: Selecting well-malted barley with lower SMM content can help limit the potential for DMS production in the first place. Additionally, roasted malts (which contain little to no SMM) are often used in darker beer styles, where DMS is less of a concern.

- Post-Brewing Practices: Proper beer handling after fermentation, such as ensuring proper carbonation and storage at the right temperature, can also help prevent DMS from developing or becoming more pronounced.

When DMS is Desired

While most beers benefit from avoiding DMS, there are cases where the presence of a low level of DMS can be desirable. Some beer styles, like certain traditional Czech Pilsners, might have a faint DMS presence that enhances the “fresh corn” or “grainy” flavor. These beers rely on a balance where the DMS doesn’t dominate, but instead contributes to the overall character.

While most beers benefit from avoiding DMS, there are cases where the presence of a low level of DMS can be desirable. Some beer styles, like certain traditional Czech Pilsners, might have a faint DMS presence that enhances the “fresh corn” or “grainy” flavor. These beers rely on a balance where the DMS doesn’t dominate, but instead contributes to the overall character.

It’s also worth noting that certain beer styles with a more robust malt backbone or high hop character may mask DMS, allowing for more flexibility in its presence.

Conclusion

Dimethyl sulfide is a sulfur compound that can profoundly impact the aroma and flavor profile of beer, often in an undesirable way. Understanding the sources of DMS and implementing control techniques during the brewing process is crucial for minimizing off-flavors and ensuring a clean, well-balanced beer. In most styles, it is preferred to avoid using DMS . However, certain traditional styles may choose to use it in limited amounts to add depth to their character. Brewers who carefully manage the boiling, fermentation, and cooling phases of brewing will produce beers that are free of this off-flavor. This resulting in a more enjoyable and high-quality beer.

Written by: Kory Davis- BSI Quality Specialist